What is an LED?

An LED is a semiconductor chip that generates light when current is applied in the right conditions, which is very different from any other technology currently used in lighting. These chips (known as dies), are assembled in a structure that helps support and protect the dies and the electrical connections. This structure is generally known as a package. Depending on the type of package and the desired characteristics, there may be one or more LED dies per package. The different types of LED packages have different strengths and weaknesses that impact the package’s applicability in lighting. Of note, LEDs are more sensitive to temperature than other types of lighting, and anything from lifetime to current to chromaticity can be impacted by the operating temperature.

applied in the right conditions, which is very different from any other technology currently used in lighting. These chips (known as dies), are assembled in a structure that helps support and protect the dies and the electrical connections. This structure is generally known as a package. Depending on the type of package and the desired characteristics, there may be one or more LED dies per package. The different types of LED packages have different strengths and weaknesses that impact the package’s applicability in lighting. Of note, LEDs are more sensitive to temperature than other types of lighting, and anything from lifetime to current to chromaticity can be impacted by the operating temperature.

Are there different types of LED?

There are currently over 500 different types of quality LED chips in todays market place. This can be confusing when a consumer sees multiple LED products with largely varied prices, shapes, sizes and looks. Often times when looking at LED products, customers will see the words “CREE Chips”. At our last count, Cree (Largest US Manufacturer – Publicly traded in the NYSE), or Nichia (Largest Asian Manufacturer) each manufacturers over 80 different chips. The best way to divide these LED chips is to classify them as Low Power LED and High Power LED. So in essence, just because a manufacturer claims to have Cree or Nichia or another brand LED Chip, does not mean that the LED product you are purchasing is of the “Light Quality” that you would expect to be purchasing. For this we must reference to the lumens per watt (LPW), which measures the brightness of the product to its energy consumption. The next step is to measure the quality of manufacturing involved, i.e welds and heat management. The final step is choosing an appropriate color of light being produced, and the beam spread of the product through the quality of optics used to disperse and focus the light.

What are Low Power LED’s?

Low Power LEDs come in two main categories, these are the lamp type and the surface mount type (also known as an SMD). In each category there are available in a number of different shapes, power levels, and sizes. These are distinguished and referred to as low power because they typically run very low current levels, in the tens of milliamps rather than hundreds of milliamps that the high power LEDs run at. This means that they will, by nature, produce less light, but also will have different applications in lighting.

Low Power LEDs come in two main categories, these are the lamp type and the surface mount type (also known as an SMD). In each category there are available in a number of different shapes, power levels, and sizes. These are distinguished and referred to as low power because they typically run very low current levels, in the tens of milliamps rather than hundreds of milliamps that the high power LEDs run at. This means that they will, by nature, produce less light, but also will have different applications in lighting.

Lamp-type LED packages are the type that most people are already familiar with, and are used in numerous applications as indicator lights or other applications where the requirement is that light must be seen. They use a low power LED die which is placed in a tiny reflector, and then encased in a transparent plastic material. The reflector extracts much of the light generated by the LED die and then the shape of the plastic encasement acts as a lens to give a light distribution, which varies depending on the shape of the encasement. Partially due to the plastic encapsulation (which has poor heat transfer properties), many of these LED packages will depreciate from their initial light output quickly. In some cases these LED packages can fall to 50% of their initial brightness within a few thousand hours. These LED packages are appropriate for indicators, and very minor back lighting applications (such as buttons or switches), but do not generate or maintain enough light for use in a general lighting application.

Surface Mount LED packages have more in common with high power LEDs in form factor and properties than they do the lamp type LED packages. These LED packages consist of one or more LED dies (still low power) in a single, typically flat, package. The package typically consists of either a ceramic or plastic reflector, and they are encapsulated in a protected substance, and the package is mounted to a PCB board. The orientation on a PCB board, as well as the configuration of the electrical contacts within the package, allows much better heat transfer properties in this type of configuration. This allows these low power LED dies to operate cooler, and reduce their light depreciation over time to levels more appropriate for use in lighting. This type of low power LED package has the potential to be useful in lighting where large arrays of them can be combined together to produce significant, usable light. This is also an economical alternative, as while SMD type packages can be more expensive than the lamp type packages, they are much less expensive than high power LED packages.

Surface Mount LED packages have more in common with high power LEDs in form factor and properties than they do the lamp type LED packages. These LED packages consist of one or more LED dies (still low power) in a single, typically flat, package. The package typically consists of either a ceramic or plastic reflector, and they are encapsulated in a protected substance, and the package is mounted to a PCB board. The orientation on a PCB board, as well as the configuration of the electrical contacts within the package, allows much better heat transfer properties in this type of configuration. This allows these low power LED dies to operate cooler, and reduce their light depreciation over time to levels more appropriate for use in lighting. This type of low power LED package has the potential to be useful in lighting where large arrays of them can be combined together to produce significant, usable light. This is also an economical alternative, as while SMD type packages can be more expensive than the lamp type packages, they are much less expensive than high power LED packages.

Some companies market LED “bulbs” with large quantities of this type of LED package that are contained in a standard lamp shape (such as a glass PAR shell), but these products will almost always result in disappointmentif they are expected to produce usable light over an extended period of time. It is simply a misapplication of the technology.

What are High power LED’s?

High Power LED packages are always of surface mount form factor (meaning single or multiple high power dies in a package) and get their name from running hundreds of milliamps per chip and generate a much more useful amount of light. Whereas Low Power LEDs generate comparatively little heat, these higher power versions do generate enough heat to make its management a concern. This is why the surface mount configuration, with better heat transfer properties, is essentially a requirement in using high power LED dies. These LED packages are more expensive, as they require a larger portion of semi conductor and require a very high grade of semiconductor material to operate effectively and efficiently at high currents. Despite this premium high power LEDs also have the most potential for use in replacing less efficient sources of lighting in general (and specialized) lighting applications.

High Power LED packages are always of surface mount form factor (meaning single or multiple high power dies in a package) and get their name from running hundreds of milliamps per chip and generate a much more useful amount of light. Whereas Low Power LEDs generate comparatively little heat, these higher power versions do generate enough heat to make its management a concern. This is why the surface mount configuration, with better heat transfer properties, is essentially a requirement in using high power LED dies. These LED packages are more expensive, as they require a larger portion of semi conductor and require a very high grade of semiconductor material to operate effectively and efficiently at high currents. Despite this premium high power LEDs also have the most potential for use in replacing less efficient sources of lighting in general (and specialized) lighting applications.

The increased current through these devices increases heat management importance over that of low power products, which is why most high power products will be mounted in a structure that will help dissipate heat. This is why most of the High Power products use a complex aluminum heat sink as housing for the LED lamps, and why most of our manufacturers have chosen to mount them on a metal core printed circuit boards.

So many LED’s look alike, what’s best for me?

This can be a daunting task when faced with so many different prices on LED lamps. Every day manufacturers are surfacing, that promise to deliver high quality LED products, but may only disappoint you. When a manufacturer (Many whom you have never heard of) wants to bring to market an LED lamp, they will out source components from China. This reduces the cost of having to create tooling for the lamp body. Often times these lamps may have the exact same outer appearance. It is what’s inside that matters most. Low power LED’s housed in a high power LED outer shell, are still low power. When a consumer sees what by all outer appearances is a high power led but carries a much lower price, you can be assured you are getting what you have paid for. When purchasing LED products, it is assuring to purchase lamps where you are issued a Brand Name product from a company with firm roots in the United States, such as Halco, Superior Life, and many more from major distributors. This is of extreme importance because you need to have consumer recourse if a product should fail prematurely. Online companies offering really great pricing often import these lamps through the mail from China. In that circumstance, you as a consumer have little to no recourse should a problem ever arise, nor can you trust that you are truly getting a high power LED product that you can depend on for years to come.

This can be a daunting task when faced with so many different prices on LED lamps. Every day manufacturers are surfacing, that promise to deliver high quality LED products, but may only disappoint you. When a manufacturer (Many whom you have never heard of) wants to bring to market an LED lamp, they will out source components from China. This reduces the cost of having to create tooling for the lamp body. Often times these lamps may have the exact same outer appearance. It is what’s inside that matters most. Low power LED’s housed in a high power LED outer shell, are still low power. When a consumer sees what by all outer appearances is a high power led but carries a much lower price, you can be assured you are getting what you have paid for. When purchasing LED products, it is assuring to purchase lamps where you are issued a Brand Name product from a company with firm roots in the United States, such as Halco, Superior Life, and many more from major distributors. This is of extreme importance because you need to have consumer recourse if a product should fail prematurely. Online companies offering really great pricing often import these lamps through the mail from China. In that circumstance, you as a consumer have little to no recourse should a problem ever arise, nor can you trust that you are truly getting a high power LED product that you can depend on for years to come.

Can LED replace any bulb?

Unlike a filament from an incandescent lamp, an arc-tube from a HID lamp, or the phosphor on a fluorescent tube, the emission of light from an LED is not Omnidirectional; that is it does not radiate in all directions uniformly. It is difficult to project light through a circuit board and heat sink, so the light from an LED is emitted from the top of the chip. This means at a theoretical best, an LED can project light in a hemispherical pattern, in reality most bare LED chips project light in a 120 to 140 degree cone. While there are some experiments in laboratories utilizing transparent substrates that may be able to further expand this distribution, these are not commercially available at this time and if and when they are, there would still be the limitation of the mounting surface and heat sinking attachment. This is why there is not currently a true “A” lamp replacement using LED technology. There are some novel methods that are producing more acceptable distributions for an omni-directional light source out of an LED, they are difficult and still suffer limitations in how much light is possible and can suffer in efficiency, depending on the approach. The most that is typically possible of an “A” lamp like LED is a distribution pattern similar to an R-type reflector lamp, directional but broad and relatively even. Despite these limitations, there are uses for a higher efficiency, long lived directional light source, and products can be made to take advantage of this.

To better direct light coming from an LED, some products such as the ProLED from Halco use what is called a secondary optic. This is a lens (although there are reflectors available) that attaches to the chip holding the LED package mechanically or through adhesive and directs the light into a different pattern (such as a narrow or a wide flood pattern). The quality of this optic affects the optical efficiency, or the amount of light that is actually projected compared to the amount of light generated by the LED. By taking advantage of the directional characteristic of LEDs, and using high quality optics, effective general lighting can be achieved with LED high power lamps.

To better direct light coming from an LED, some products such as the ProLED from Halco use what is called a secondary optic. This is a lens (although there are reflectors available) that attaches to the chip holding the LED package mechanically or through adhesive and directs the light into a different pattern (such as a narrow or a wide flood pattern). The quality of this optic affects the optical efficiency, or the amount of light that is actually projected compared to the amount of light generated by the LED. By taking advantage of the directional characteristic of LEDs, and using high quality optics, effective general lighting can be achieved with LED high power lamps.

How do LED’s produce good color?

There are no true white LEDs that are commercially viable. Every type of material used in the chip part of the LED that produces light generates a color, but none of those colors are white. All LEDs produce a color, red, green, yellow, or blue (note that IR and UV LEDs do exist as well). The two methods for generating white light are to either use multiple LED chips and mix the light, or to use a phosphor with a single color light (usually blue) to generate white light.

The color mixing method is (with current technology) less efficient, particularly in a high power setting, but through the use of advanced controls does allow virtually any color to be produced by varying the intensity of the multiple LEDs. If the efficiency gap of utilizing green LED die material at high currents is solved, there is significant potential in this method.

The phosphor coating method is currently much more efficient at producing light. This coating process does have limitations as well, and that is in the variation in color temperature and chromaticity. The phosphor coating composition and thickness affect the color temperature, color rendering, and light output. In addition to this, the phosphors have a ‘response curve’, which means that the exact wavelength of the blue LED die used in this package will have an impact on the final light output as well. Generally speaking, warmer color temperature LED packages will have more of the phosphor coating than a cooler color temperature LED. Additionally, some companies use the addition of a red phosphor as well to help with the color quality and color rendering. Increasing phosphor thickness and adding an additional phosphor, unlike fluorescent lamps, will lower the output of the LED package, as while these phosphors are very efficient, they are not 100% efficient, do produce some losses, and can have an impact on thermal management. To deal with these manufacturing variations, manufacturers of LED packages will divide their products up into “bins” which will have a defined range of characteristics. By selecting a bin, the resulting product will fall within a reasonably predictable range of color and performance characteristics. While the bins offered by manufacturers of LED packages are getting smaller, there can still be variation in the color characteristics between production runs. These are the trade-offs of using phosphors to produce white light.

The phosphor coating method is currently much more efficient at producing light. This coating process does have limitations as well, and that is in the variation in color temperature and chromaticity. The phosphor coating composition and thickness affect the color temperature, color rendering, and light output. In addition to this, the phosphors have a ‘response curve’, which means that the exact wavelength of the blue LED die used in this package will have an impact on the final light output as well. Generally speaking, warmer color temperature LED packages will have more of the phosphor coating than a cooler color temperature LED. Additionally, some companies use the addition of a red phosphor as well to help with the color quality and color rendering. Increasing phosphor thickness and adding an additional phosphor, unlike fluorescent lamps, will lower the output of the LED package, as while these phosphors are very efficient, they are not 100% efficient, do produce some losses, and can have an impact on thermal management. To deal with these manufacturing variations, manufacturers of LED packages will divide their products up into “bins” which will have a defined range of characteristics. By selecting a bin, the resulting product will fall within a reasonably predictable range of color and performance characteristics. While the bins offered by manufacturers of LED packages are getting smaller, there can still be variation in the color characteristics between production runs. These are the trade-offs of using phosphors to produce white light.

Some light quality advantages they have are that the spectrum of a white phosphor based LED is much smoother than a compact fluorescent lamp (providing light emission over a broad range of spectrum), and is capable of providing high quality light. In additional comparisons to CFL technology, an LED product can achieve instant full brightness, and is unaffected by switching, all without the use of mercury. RGB based white lights can be used to create dramatic color changing effects.

Why choose LED over Halogen, or CFL?

An advantage that LED products have over equivalent halogen lamps is tremendous energy savings, and a beam that projects neither heat nor UV radiation, making LEDs a safe product to use when highlighting without concern of overheating or fading of the product.

Lifespan

The long life of properly designed LED products makes them ideal for a situation where light failure can cost a lot of time, effort, and money. Examples of such are high-mounted recess and track lighting, where changing the bulb could be both dangerous and time consuming (such as in a hotel lobby, or in the atrium of a building). With upwards of 60,000 hour useful lifespan in LED products, years of trouble free lighting can be achieved, easily saving money in labor and replacement costs for the equivalent of three to four CFL changes, or ten to fifteen halogen lamp changes. Useful lifespan is defined as when the LEDs depreciate to 70% of their initial output, in lumens. The lamp will continueto operate far beyond that, but with additional lumen depreciation.

Energy Savings

Compare for example, a 75 Watt halogen lamp producing 1000 lumens of light. This type of lamp operates at a consumption rate or LPW (lumens per watt) of 13.3. In using a direct replacement LED product it only takes on average 11 to 14 watts of light with a LPW rate of 90.0. In this scenario, the LED is 676% more energy efficient than Halogen, thus resulting in an energy savings of 84%.

Product Presentation

The last thing you want when using light to highlight a point of interest is for that light to damage or impair what you are highlighting. Whether the product is a delicate food that is sensitive to heat, a painting whose vivid details could be dulled by UV, or a diamond ring that has to be comfortable when it comes out of the case, an LED directional light is a great solution.

Safety

There is no glass in most LED products to break, very little heat compared to a searing halogen reflector, an no mercury to poison the environment. When the safety of your environment (working and natural) matters to you or your customers, a ProLED lamp is a great choice to suit your lighting needs. A lamp that won’t be in the landfill for years, won’t poison drinking water, and won’t shatter sending slivers of glass flying. Further there is tremendous reduction in labor costs and liability by reducing the number of times someone must work on or replace an electrical component from a ladder.

Fixture Requirements

All of the LED products come with a mention of not using them in totally enclosed fixtures, which causes some confusion and concern. To clarify, the term “totally enclosed” in this instance means that there is no airflow around the LED lamp, and the reason goes back to thermal management. LEDs do generate some heat, and while not as much as any of the other types of light, in a fixture with zero airflow, the aluminum body is unable to act as a heat-sink, and reduces the life of the electrical components in the LED lamp. It is important to note the specific wording of “outdoor use” on an LED product that is exposed to the elements. This means mounting or placement where water, rain and heavy moisture build-up can occur. Use in recessed cans under walkways is acceptable in warmer, dryer climates. The second main drawback of LED based products is that they are much more sensitive to heat buildup than many other technologies. There are many applications where LEDs may still be inappropriate at the current time, where the ambient temperature is high enough that the long life of an LED product would be compromised significantly. Most LED products cannot be totally enclosed unless very low wattage or specifically designed for this application, and this includes many of the insulated recessed can lights.

What are the drawbacks of LED?

LED Drawbacks All of the aforementioned benefits of LED based lighting products do not come without a price. One of thelargest drawbacks of LED based products is literally the price. High quality LED packages, with predictable and reliable color quality and output, are still very expensive when considering their initial cost on a lumen per watt basis. Using more LED packages will generally result in a better efficiency, but is then tempered by the fact that it adds considerably to the product cost. An LED lighting product is essentially an electrical appliance that produces light, and is more complex than many other sources. In addition to the LEDs themselves, the aluminum heat sinks, printed circuit boards, drivers, and optical control devices are all relatively expensive components to produce. Improvements in LED efficiency has the potential to reduce the overall initial cost, and as demand increases, economies of scale will likely bring the initial cost of LED products down over time, but they are unlikely to ever be as initially inexpensive as older, simpler, but much less efficient incandescent technology. Their long life requires a different approach to considering cost, where cost of ownership over time. When considering the purchase of LED, you must take into account the number of Incandescent or Halogen lamps one would buy to cover the same time period (60,000 hours), the energy and labor maintenance savings in total. Often consumers will find that the LED, though a higher upfront cost, yields a return on investment measured well over 600%.

The second main drawback of LED based products is that they are much more sensitive to heat buildup than many other technologies. There are many applications where LEDs may still be inappropriate at the current time, where the ambient temperature is high enough that the long life of an LED product would be compromised significantly. Most LED products cannot be totally enclosed unless very low wattage or specifically designed for this application, and this includes many of the insulated recessed can lights.

Despite the drawbacks or challenges in LED lighting technology, they have significant potential to change the landscape of lighting forever, and in dramatic ways that far exceed the flexibility of any other commercially available lighting technology.

Special thanks to: David Nelkin; Director of Product Technologies – Halco Lighting, and Tom Gregg; Product Engineer – PQL Lighting for assembling this information on behalf of all lighting professionals.

In the pursuit of reducing energy waste in commercial buildings, many customers often overlook the most obvious lighting fixtures. These are the exit signs located above doors and egress areas. This small and often neglected fixture can result in significant energy savings and labor/maintenance savings. Most consumers are aware of inexpensive LED retrofits that can replace

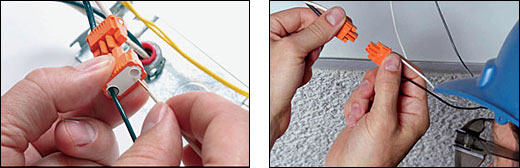

In the pursuit of reducing energy waste in commercial buildings, many customers often overlook the most obvious lighting fixtures. These are the exit signs located above doors and egress areas. This small and often neglected fixture can result in significant energy savings and labor/maintenance savings. Most consumers are aware of inexpensive LED retrofits that can replace  Radionic has designed and developed an energy saving LED Kit that is truly universal for applications of upgrading many OEM Exit Signs utilizing incandescent, fluorescent, and CFL bulbs. This proprietary design meets LEED Certification requirements and provides energy savings up to 80% yielding an amazing cost savings of $37.00 per fixture / per year. with only 4.1 watts of crisp bright white LED, the ZXE-5000-i and ZXE-5000-e offer true solid state technology with (i) Internal and (E) External located LED Drivers. The Radionic LED kit can easily be installed in less than 12 minutes by

Radionic has designed and developed an energy saving LED Kit that is truly universal for applications of upgrading many OEM Exit Signs utilizing incandescent, fluorescent, and CFL bulbs. This proprietary design meets LEED Certification requirements and provides energy savings up to 80% yielding an amazing cost savings of $37.00 per fixture / per year. with only 4.1 watts of crisp bright white LED, the ZXE-5000-i and ZXE-5000-e offer true solid state technology with (i) Internal and (E) External located LED Drivers. The Radionic LED kit can easily be installed in less than 12 minutes by  With the highest requirements in the country for emergency and egress lighting, the ZXE-5000 series LED Kit is UL-924 listed and the only approved LED Exit Sign Retrofit certified by the Chicago and New York Fire Departments. The ZXE-5000 kits are eligible for various incentives and rebates including those offered by ComEd and LEED Certification.

With the highest requirements in the country for emergency and egress lighting, the ZXE-5000 series LED Kit is UL-924 listed and the only approved LED Exit Sign Retrofit certified by the Chicago and New York Fire Departments. The ZXE-5000 kits are eligible for various incentives and rebates including those offered by ComEd and LEED Certification.

One of the biggest drawbacks in years past was the use in commercial bathrooms. If a bathroom stall was in use, the partitions would block the sensor from detecting that there was an occupant in the restroom, and the lights may turn out while the bathroom is still in use. Often perople would find themselves waving a hand over the stall door to try and activate the sensor again. This problem has been rectified with the creation of a “Nocc Sensor”, or Noise and Heat Activated Switch. The Nocc Sensor has a decibel rated noise sensor capable of detecting so much as a murmur or footstep, preventing it from turning off even if direct view of an occupant is blocked.

One of the biggest drawbacks in years past was the use in commercial bathrooms. If a bathroom stall was in use, the partitions would block the sensor from detecting that there was an occupant in the restroom, and the lights may turn out while the bathroom is still in use. Often perople would find themselves waving a hand over the stall door to try and activate the sensor again. This problem has been rectified with the creation of a “Nocc Sensor”, or Noise and Heat Activated Switch. The Nocc Sensor has a decibel rated noise sensor capable of detecting so much as a murmur or footstep, preventing it from turning off even if direct view of an occupant is blocked.